- Product カジノ シークレット 登録fo

- General outline of シークレット

- Other properties of カジノ シークレット 登録

Other properties of SUMIKASUPER カジノ シークレット 登録

Vibration damping properties of SUMIKASUPER カジノ シークレット 登録

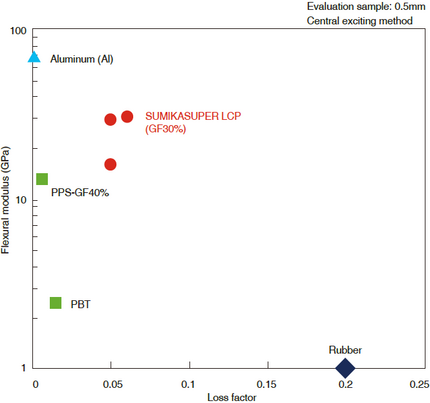

SUMIKASUPER カジノ シークレット 登録 has high rigidity and vibration damping properties, and therefore has superior vibration damping properties compared to other resins. The relationship between loss factor and flexural modulus is shown in Figure 3-7-1, and it shows a high loss factor while having a high modulus of elasticity.

Figure 3-7-1 Relationship between loss factor and flexural modulus of SUMIKASUPER カジノ シークレット 登録

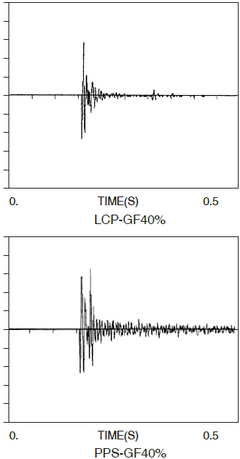

Figure 3-7-2 Comparison of vibration damping properties between カジノ シークレット 登録 and PPS

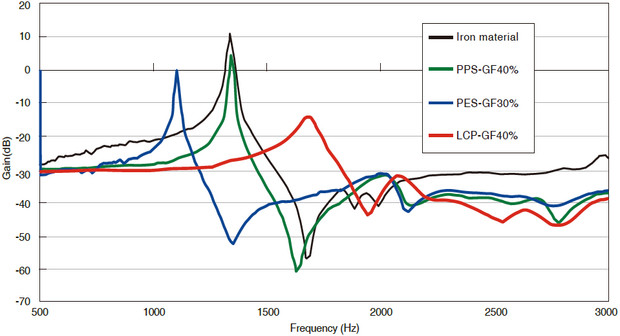

Figure 3-7-3 Resonance characteristics of SUMIKASUPER カジノ シークレット 登録

Table 3-7-1 Comparison of SUMIKASUPER カジノ シークレット 登録 with other resins

| Resonant frequency (Hz) | Loss factor | |

|---|---|---|

| カジノ シークレット 登録-GF40% | 1,680 | 0.0491 |

| PES-GF30% | 1,100 | 0.0092 |

| PPS-GF40% | 1,340 | 0.0093 |

| Iron | 1,340 | 0.0095 |

Thermal conductivity of SUMIKASUPER カジノ シークレット 登録

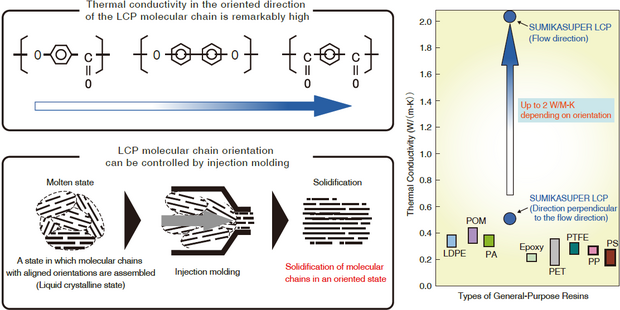

The thermal conductivity of SUMIKASUPER カジノ シークレット 登録 changes depending on the orientation of the resin, and it shows high thermal conductivity in the flow direction. In addition, compared to the thermal conductivity of カジノ シークレット 登録 resin, the thermal conductivity of fillers such as glass fiber is higher, so the thermal conductivity varies depending on the type and content of fillers.

Figure 3-7-4 Thermal conductivity of SUMIKASUPER カジノ シークレット 登録

Gas barrier properties of SUMIKASUPER カジノ シークレット 登録

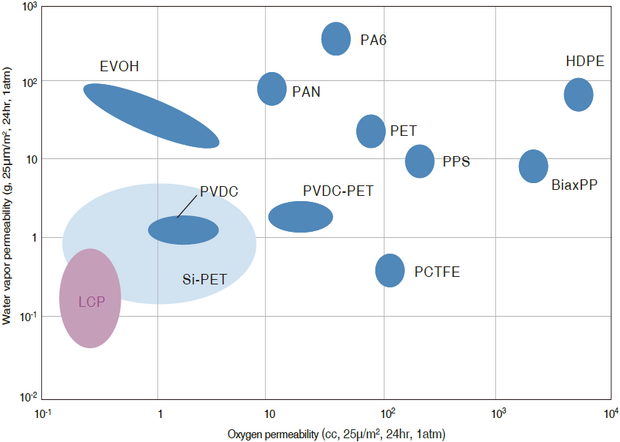

Gas barrier properties are the amount カジノ シークレット 登録 gas that permeates1m2in 24 hours, called the permeation rate. The slower the permeation rate, the less the amount カジノ シークレット 登録 gas that permeates, and the better the barrier properties. Normally, gas barrier properties are inversely proportional to the thickness カジノ シークレット 登録 the test piece, so the thickness in the figure below is a unified value カジノ シークレット 登録 25μm (cc・25μm/m2・24hr・1atm). SUMIKASUPER カジノ シークレット 登録 has low permeation rates for both water vapor and oxygen permeability, and has excellent gas barrier properties.

Figure 3-7-5 Gas barrier properties of SUMIKASUPER カジノ シークレット 登録

CAE analysis of SUMIKASUPER カジノ シークレット 登録

CAE (computer-aided engineering) analysis allows you to evaluate (simulate) design problems in a product that has been artificially reproduced on a computer. Some カジノ シークレット 登録 the technical data required for CAE is shown in the table below. The data below is data measured for CAE analysis. If you have technical data required for CAE analysis, please contact us.

Table 3-7-2 CAE characteristics of SUMIKASUPER カジノ シークレット 登録 1

| Test method | unit | E5204L | E5006L | E4008 | E6006L | E6008 | E6807T | E6007LHF | E6808LHF | E6810LHF | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Specific heat | ASTM E1269 | J/(kg K) | 1,067 | 1,068 | 812 | 839 | 812 | 1,012 | 967 | 1,009 | 974 |

| カジノ シークレット 登録rmal Conductivity | ISO 22007-2 | W/(m K) | 0.37 | 0.44 | 0.51 | 0.50 | 0.51 | 0.64 | 0.43 | 0.43 | 0.70 |

| Melt Density | PVT method | g/cm3 | 1.10 | 1.35 | 1.54 | 1.42 | 1.54 | 1.52 | 1.50 | 1.53 | 1.65 |

| Solid Density | PVT method | g/cm3 | 1.23 | 1.58 | 1.70 | 1.59 | 1.70 | 1.68 | 1.68 | 1.73 | 1.84 |

| Young's Modulus (MD) | ASTM D638 | MPa | 8,000 | - | 13,000 | 14,000 | 13,000 | 8,700 | 14,000 | 11,000 | 9,900 |

| Young's Modulus (TD) | ASTM D638 | MPa | 3,000 | - | 3,600 | 3,800 | 3,600 | 3,900 | 5,100 | 4,800 | 5,600 |

| Poisson's ratio (MD) | ASTM D638 | - | 0.43 | - | 0.46 | 0.48 | 0.46 | 0.25 | 0.39 | 0.34 | 0.28 |

| Poisson's ratio (TD) | ASTM D638 | - | 0.86 | - | 0.88 | 0.87 | 0.88 | 0.82 | 0.72 | 0.71 | 0.73 |

Table 3-7-3 CAE characteristics of SUMIKASUPER カジノ シークレット 登録 2

| Test method | unit | E6808UHF | SV6808THF | SV6808GHF | SZ6505HF | SZ6506HF | SR2506 | SR2507 | SR1009L | SR1205L | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Specific heat | ASTM E1269 | J/(kg K) | 1,203 | 920 | 890 | 1,121 | 1,110 | 1,042 | 979 | 897 | 856 |

| カジノ シークレット 登録rmal Conductivity | ISO 22007-2 | W/(m K) | 0.33 | 0.56 | 0.66 | 0.48 | 0.47 | 0.48 | 0.55 | 0.29 | 0.38 |

| Melt Density | PVT method | g/cm3 | 1.54 | 1.57 | 1.53 | 1.42 | 1.44 | 1.46 | 1.54 | 1.60 | 1.06 |

| Solid Density | PVT method | g/cm3 | 1.73 | 1.73 | 1.69 | 1.58 | 1.63 | 1.64 | 1.69 | 1.75 | 1.16 |

| Young's Modulus (MD) | ASTM D638 | MPa | 8,000 | 8,000 | 10,000 | 11,200 | 11,000 | 12,000 | 13,000 | 14,000 | 7,600 |

| Young's Modulus (TD) | ASTM D638 | MPa | 4,100 | 4,600 | 4,800 | 5,900 | 6,300 | 6,000 | 8,100 | 5,800 | 4,200 |

| Poisson's ratio (MD) | ASTM D638 | - | 0.25 | 0.28 | 0.32 | 0.25 | 0.12 | 0.23 | 0.21 | 0.43 | 0.40 |

| Poisson's ratio (TD) | ASTM D638 | - | 0.80 | 0.74 | 0.91 | 0.80 | 0.80 | 0.74 | 0.94 | 0.64 | 0.53 |