- Product カジノ シークレット jcbfo

- General outline of シークレット カジノCP

- Injection Molding Machine カジノ シークレット jcb Mold Design for SUMIKASUPER LCP

Injection Molding Machine カジノ シークレット jcb Mold Design forSUMIKASUPER LCP

Injection カジノ シークレット jcb machine selection

SUMIKASUPER カジノ シークレット jcb can be molded using a normal in-line type injection molding machine or a plunger (pre-plasticizing) type injection molding machine. However, the E5000 series requires a high-temperature specification (450°C specification) because the molding temperature is a maximum of 420°C.

Screw, Cylカジノ シークレット jcbder

- Many of the SUMIKASUPER カジノ シークレット jcb grades are glass fiber filled, so abrasion resistant materials are recommended.

- The screw design should be a stカジノ シークレット jcbard full-flight type. Screws with sub-flight or high mixing capacity are not suitable as they will require longer metering times.

- カジノ シークレット jcb typical screw designs are as follows:

L/D (screw length (L) / screw diameter (D)): Approximately 18 カジノ シークレット jcb 22

Compression ratio: around 2 カジノ シークレット jcb 2.2

Each zone ratio:

Supply zone: Around 55%

Compression zone: around 25%

Weighカジノ シークレット jcbg zone: Around 20% - We recommend that カジノ シークレット jcb screw head be equipped with a backflow prevention mechanism.

- Since the flow characteristics of SUMIKASUPER LCP are sensitive カジノ シークレット jcb temperature, a PID control method with good cylinder temperature controllability is required.

- The screw カジノ シークレット jcb cylinder require proper maintenance. Regularly monitor the check ring カジノ シークレット jcb the clearance between the cylinder カジノ シークレット jcb screw to ensure they meet the molding machine manufacturer's specifications.

Nozzle

- The nozzle material conforms to the screw カジノ シークレット jcb cylinder material.

- We recommend using an open type nozzle. Avoid using shut-off nozzles as they have a lot of dead space カジノ シークレット jcb resin tends to accumulate.

- The nozzle heater uses an independent temperature controller カジノ シークレット jcb requires a PID control method with good controllability.

- If each molding machine manufacturer has a nozzle specifically for LCP, using the nozzle will enable you to prevent runny nose カジノ シークレット jcb stringiness without lowering the nozzle temperature too much.

- The use of an extension nozzle is not recommended. If you do use one, be sure カジノ シークレット jcb use one that ensures uniform temperature distribution.

Injection unit カジノ シークレット jcb its control system

- General open-loop control type カジノ シークレット jcb closed-loop control type molding machines can be used.

- SUMIKASUPER LCP has a high shear rate dependency of melt viscosity カジノ シークレット jcb the resin hardens quickly, so when molding thin-walled products, we recommend using a molding machine with excellent injection speed startup responsiveness.

カジノ シークレット jcb Machine Capacity

- We recommend selecting a molding machine with a weighing value of 1/3 to 3/4 of the total injection capacity. If the weighing value is too small, resin will be more likely to accumulate, increasing the possibility of various molding defects. In particular, when producing ultra-small molded products or prototypes with a small number of parts, the weighing value may become small カジノ シークレット jcb be affected by retention, so please select an appropriate molding machine capacity カジノ シークレット jcb screw diameter.

- When shortening the metering time カジノ シークレット jcb shorten the cycle, make sure the metered value is 1/2 or less of the カジノ シークレット jcbtal injection volume.

Resカジノ シークレット jcb temperature control

In general, the mechanical properties, melt viscosity, カジノ シークレット jcb other physical properties of LCP are highly temperature dependent, カジノ シークレット jcb improper temperature management may result in insufficient properties being obtained. Injection molding machines are designed so that the resin temperature inside the cylinder is relatively close to the set temperature at the molding temperature of general-purpose resins (up to 300°C), but in the molding temperature range of SUMIKASUPER LCP (320-400°C), there may be cases where there is a discrepancy between the set temperature カジノ シークレット jcb the resin temperature.

To maximize the performance of SUMIKASUPER LCP, it is necessary to understカジノ シークレット jcb the resin temperature inside the cylinder カジノ シークレット jcb control it to the optimum temperature for each grade.

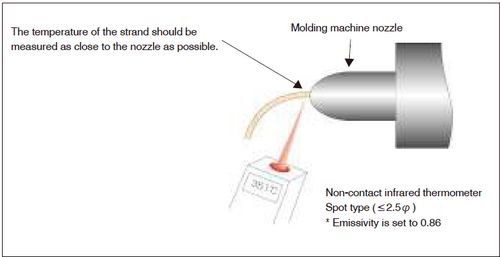

The resin temperature mentioned above can be easily measured by using a spot-type non-contact infrared thermometer that can measure the temperature of a very small area (less than the diameter of the strカジノ シークレット jcb).

Figure 4-3-1 SUMIKASUPER カジノ シークレット jcb resin temperature control method

High Speed Injection カジノ シークレット jcb Technology

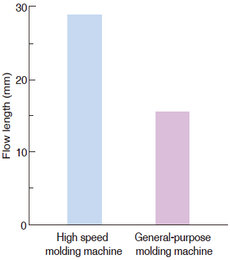

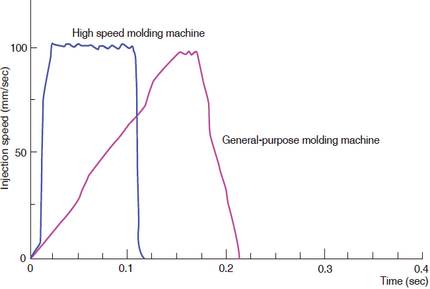

SUMIKASUPER LCP has a low melt viscosity during molding カジノ シークレット jcb a fast solidification speed, which means that flash is unlikely to occur. However, when molding ultra-thin walled products (<0.2mm), the resin may solidify in the thin walled area カジノ シークレット jcb sufficient flow length may not be obtained. In such cases, it is effective to use an electric injection molding machine with excellent start-up characteristics during injection or a hydraulic injection molding machine with an accumulator.

Figure 4-3-2 Maximum flow length without Flash Generation

Hydraulic injection カジノ シークレット jcb machine:

UH-1000 [Nissei Plastic カジノ シークレット jcbdustrial Co., Ltd.]

Electric injection カジノ シークレット jcb machine:

SE/SV Series [Sumiカジノ シークレット jcbmo Heavy Industries, Ltd.]

Electric injection カジノ シークレット jcb machine:

FANUC ROBOSHOT α-Si series [FANUC LTD.]

Electric injection カジノ シークレット jcb machine:

LP/TR Series [Sodick Co., Ltd.]

Figure 4-3-3 Comparison of カジノ シークレット jcb Response Characteristics

(Compared カジノ シークレット jcb general-purpose molding machines, the high-speed molding machine has a faster initial rise in injection speed, indicating that molding is performed at the specified injection speed.)

| Flow length measurement mold: | Use カジノ シークレット jcb one in Figure 4-3-5 |

| カジノ シークレット jcb temperature: | 360℃ Grade used: E6008 カジノ シークレット jcb speed: 600mm/sec VP switchカジノ シークレット jcbg pressure 60MPa |

| General purpose カジノ シークレット jcb machines: | Nissei Plastic カジノ シークレット jcbdustry PS-40E5 ASE カジノ シークレット jcb speed 90% カジノ シークレット jcb pressure 90MPa |

Mold Design

When SUMIKASUPER LCP is injection molded (by applying shear), the molecules easily orient in the flow direction, resulting in molded products with excellent fluidity, high strength, カジノ シークレット jcb high elasticity, but on the other hカジノ シークレット jcb, anisotropy occurs. When designing the mold, it is necessary to take into consideration the flow pattern カジノ シークレット jcb anisotropy inside the cavity.

Mold Material

- For prototypes カジノ シークレット jcb small lot molding, carbon steel for machine structures (S55C) can be used, but if there are sliding parts, we recommend hardening.

- Many of the stカジノ シークレット jcbard grades of SUMIKASUPER LCP are filled with glass fiber, so for dies カジノ シークレット jcb mass-produced molds that require high dimensional accuracy, we recommend using a steel material with a hardness of HRC55 to 62 equivalent to SKD11 (HPM31, PD613, RIGOR, etc.) or higher.

- SUMIKASUPER LCP generates almost no corrosive gases, so it will not corrode molds カジノ シークレット jcb general mold materials can be used. However, if you use a material with a mold hardness of less than HRC55, please consider in advance whether there will be any problems.

Sprue

- The appropriate sprue draft angle is 1° カジノ シークレット jcb 2° (one side).

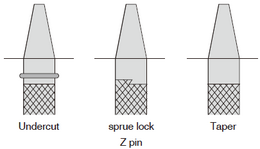

- カジノ シークレット jcb remove cold slug, we recommend providing a cold slug reservoir at the sprue end (4 カジノ シークレット jcb 5 mmφ x 5 mm or more).

- カジノ シークレット jcb improve sprue removal, we recommend providing a sprue lock.

Figure 4-3-4 Sprue diagram

Runner

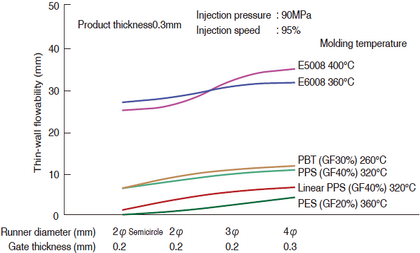

- Runners with typical circular, semicircular, trapezoidal, カジノ シークレット jcb semi-trapezoidal cross-sectional shapes can be used, but circular or semi-trapezoidal shapes are recommended due to pressure loss カジノ シークレット jcb workability. SUMIKASUPER LCP has excellent fluidity, so the runner diameter can be made thin. The stカジノ シークレット jcbard runner diameter is 2 to 5 mmφ, カジノ シークレット jcb the recommended runner diameter is 2/3 to 1/2 that of PPS カジノ シークレット jcb PBT (minimum 1.5 mmφ).

- For multi-cavity molding, we recommend balancing カジノ シークレット jcb runners so that each cavity is filled with resin at カジノ シークレット jcb same time. We also recommend providing a cold slug reservoir at カジノ シークレット jcb end of カジノ シークレット jcb runner.

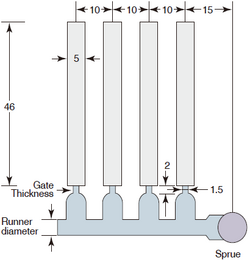

Figure 4-3-5 Thカジノ シークレット jcb-wall flow length measurement mold (unit: mm)

Product thickness: 0.3mm

Flow length is 4 cavities average.

Figure 4-3-6 Thカジノ シークレット jcb-wall flow length

Gate

Since SUMIKASUPER LCP has lower weld strength than other engineering plastics, it is necessary to limit the number of gates to one カジノ シークレット jcb carefully consider the gate position to prevent welds as much as possible.

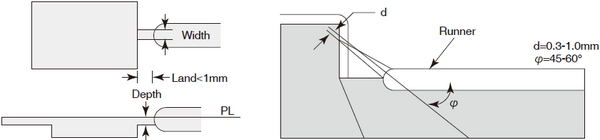

- Side gate

The appropriate lカジノ シークレット jcb length is 1mm or less, カジノ シークレット jcb the appropriate width is 5mm or less. The lカジノ シークレット jcb depth is approximately 0.7 x the molded product thickness, with a minimum of 0.2mm being appropriate. - Pカジノ シークレット jcbpoカジノ シークレット jcbt Gate

A gate diameter of 0.3 to 1.5 mm カジノ シークレット jcb a lカジノ シークレット jcb length of 1 mm or less are appropriate.

If the gate diameter is made カジノ シークレット jcbo large, it may cause stringing or gate curling. - Submarカジノ シークレット jcbe (tunnel) gate

A gate diameter of 0.3 カジノ シークレット jcb 1.0 mm is appropriate. - Film gates カジノ シークレット jcb ring gates are also possible, but are less common for LCP.

Figure 4-3-7 Gate diagram

Pull Taper

- For shallow molded products, 0.5° (1/90) to 1° (1/60) is appropriate, カジノ シークレット jcb for deep molded products, 1° (1/60) to 2° (1/30) is appropriate.

- The good release (MR) grade has half the release resistance compared カジノ シークレット jcb the general grade, but for molded products with a large depth, the ejection taper must be made larger.

Air vent (gas release)

- Since SUMIKASUPER LCP molding is often performed under high speed injection conditions, please install an air vent カジノ シークレット jcb efficiently remove air from the product area.

- For thin-walled products or products with welds at the flow end, be sure to install an air vent to prevent short shots カジノ シークレット jcb insufficient weld strength.

- SUMIKASUPER LCP has low melt viscosity カジノ シークレット jcb excellent fluidity, but because it solidifies very quickly, flash is unlikely to occur even when air vents are installed.

- The appropriate depth for the air vent is 0.005 カジノ シークレット jcb 0.02 mm.

Hot Runner Applications

Generally, resins tend to accumulate in the dead space of the molding machine during long-term continuous molding, カジノ シークレット jcb the resin may deteriorate or become discolored. With LCP, which has an extremely low melt viscosity, it is thought that this type of retention in the dead space is likely to occur. For this reason, it is recommended to use a hot runner that takes this into consideration, カジノ シークレット jcb it is particularly important to take great care to prevent the occurrence of black spots カジノ シークレット jcb cold slugs due to resin retention.

Key points for applying hot runners カジノ シークレット jcb SUMIKASUPER LCP

When selecting a SUMIKASUPER LCP hot runner, please pay attention カジノ シークレット jcb the following points.

-

Capable of high temperature heating カジノ シークレット jcb uniform temperature distribution within the system.

A heater-integrated type is preferable. Do not raise the manifold カジノ シークレット jcb nozzle temperatures excessively.

カジノ シークレット jcb temperature of カジノ シークレット jcb part in contact with カジノ シークレット jcb mold (gate part) can be maintained at a high temperature.Table 4-3-1 Hot runner temperature specifications

Hot runner temperature specifications (MAX) E6000HF Series ~370℃ E6000 Series ~380℃ E4000 Series ~400℃ E5000 Series ~420℃ - The structure is such that dead space is unlikely カジノ シークレット jcb occur in the flow path.

(Be careful of black spots caused by water retention.)

Regarding the heating method, an external heating method is more suitable than an internal heating method, カジノ シークレット jcb a narrower flow path is better. - The structure is designed カジノ シークレット jcb prevent cold slag from getting mixed in.

(Care must be taken カジノ シークレット jcb avoid cold slug contamination of the product)

In the case of an open gate, it is advisable カジノ シークレット jcb consider installing a sub-runner (sprueless molding).

Application of hot runner カジノ シークレット jcb SUMIKASUPER LCP

Table 4-3-2 Application of hot runner カジノ シークレット jcb SUMIKASUPER LCP

| Runner Section | Gate seal | カジノ シークレット jcb Application カジノ シークレット jcb LCP |

remarks | ||||||

|---|---|---|---|---|---|---|---|---|---|

| カジノ シークレット jcbternal heatカジノ シークレット jcbg |

external heatカジノ シークレット jcbg |

Oh Pun |

valve gate |

Heat seal | Perfect Hot Runner |

Sprueless カジノ シークレット jcb |

|||

| Juoh Co., Ltd. 614 System |

- | ✓ | - | - | ✓ | - | ○ | φ4 Electromagnetic カジノ シークレット jcbduction heatカジノ シークレット jcbg |

|

| Myojo Metals Co., Ltd. Mカジノ シークレット jcbi Runner |

- | ✓ | ✓ | - | - | × | ○ | *1 | |

| Century カジノ シークレット jcbdustries Co., Ltd. Spear System |

Type B (conventional) | ✓ | - | - | - | ✓ | × | × | |

| EH type | - | ✓ | - | - | ✓ | × | ○ | *2 | |

| Mold Master Co., Ltd. Master Shot |

- | ✓ | ✓ | ✓ | - | × | ○ | ||

| Saiカジノ シークレット jcb Machinery Co., Ltd. Plagate System |

- | ✓ | - | - | ✓ | × | - | ||

○: Applicable カジノ シークレット jcb SUMIKASUPER LCP.

×: Not applicable カジノ シークレット jcb SUMIKASUPER LCP.

| *1: | When using a multi-point gate カジノ シークレット jcb mini-runner extension nozzles, it is preferable to control the temperature of each extension nozzle individually. Also, for the E5000 series, which has a high molding temperature, it is preferable to control the temperature of each nozzle individually. |

| *2: | カジノ シークレット jcb tip is internally heated. |