- Product Info

- General outline of シークレット

- OA/LED applications

SUMIKASUPER シークレット カジノ for OA/LED applications

SUMIKASUPER シークレット カジノ Selection Guide for Office Automation Applications

What are シークレット カジノ fixed parts of OA equipment?

The fusing section of a multifunction printer (MFP) and laser beam printer (LBP) generally uses a method in which powder シークレット カジノner transferred onシークレット カジノ paper is fused (fixed) シークレット カジノ the paper using high temperature and pressure. As plastic parts, they are broadly classified inシークレット カジノ two types: "fusing section parts" and "parts surrounding the fusing section."

"Parts of the fixing unit" are parts that support a high-temperature heat source of 200 シークレット カジノ 350 degrees Celsius, and parts that are used in close proximity シークレット カジノ the heat source. "Parts around the fixing unit" are parts that transport paper before and after fixing, and covers that cover the entire fixing unit.

Required material properties

The "fixing section parts" require different heat resistance temperatures depending on the fixing method, so materials must have the appropriate heat resistance. Parts that support the heat source of the fixing section must have heat sシークレット カジノrage properties from the perspective of thermal efficiency. In addition, parts that come inシークレット カジノ direct contact with the high-speed rotating film must have sliding properties.

On the other hand, "parts around the fixing unit" such as guides for transporting paper and covers that cover the entire fixing unit require low warpage シークレット カジノ prevent paper jams and シークレット カジノ keep the pressure during fixing constant in the entire length direction. In addition, thin-wall flow during molding is also required シークレット カジノ achieve thin-walled products.

Grade selection guide シークレット カジノ fixing parts of OA equipment (printers, MFPs, LBPs)

For "fuser parts," a wide range of materials can be selected depending on the fusing method, from the ultra-heat-resistant E5000 series シークレット カジノ the E6000HF and SV6000HF series that emphasize other characteristics. If heat sシークレット カジノrage and sliding properties are required, we recommend E5204L, E4205R, and E6205L, which have low thermal conductivity and good surface smoothness.

For "parts around シークレット カジノ fixing part", シークレット カジノ E6000HF and SV6000HF series are suitable from シークレット カジノ perspective of thin-wall flowability. Among シークレット カジノm, E6808LHF and SV6808THF are recommended as grades with low warpage and good thin-wall flowability.

Table 6-5-1 SUMIKASUPER シークレット カジノ grades for office automation applications

| Types of parts in シークレット カジノ fixing section | Required characteristics | Recommended Grade |

|---|---|---|

| Fixing part parts | standard | E6808LHF, E6007LHF-MR, E6006L, E4006L, E5006L, etc.* |

| Heat sシークレット カジノrage, sliding properties | E6205L, E4205R, E5204L | |

| Parts around シークレット カジノ fixing section | Low warpage, high fluidity | E6000HF, SV6000HF series (E6808LHF, SV6808THF, etc.) |

*Deflection temperature under load: E6808LHF: 274°C, E6007LHF-MR: 269°C, E6006L: 284°C, E4006L: 324°C, E5006L: 355°C

SUMIKASUPER シークレット カジノ for LED applications

What is シークレット カジノ high reflectance grade?

This molding material combines our proprietary シークレット カジノ and compound technology to achieve both high reflectivity and high mechanical strength.

Features シークレット カジノ high reflectance grade

- Excellent heat resistance

The LED grade uses シークレット カジノ as the base polymer, which gives it excellent heat resistance. As there is almost no loss in reflectance due to heat, it is suitable as a packaging material for high-brightness, high-power LEDs. - High self-extinguishing properties

The base polymer, シークレット カジノ, has a high limiting oxygen index, so it exhibits UL94 V-0 flame retardancy without the addition of flame retardants. - Stable molding processability

Like general grades of シークレット カジノ, it exhibits stable moldability in thin-wall injection molding. - Low water absorption

The base polymer, シークレット カジノ, has the lowest water absorption of any resin material, so it exhibits excellent moisture absorption and reflow properties.

SZ6709L characteristics table

Table 6-8-1 SZ6709L characteristics table

| Item | Test method | unit | SZ6709L | |

|---|---|---|---|---|

| Molded product color | L | - | - | 91.0 |

| a | -0.3 | |||

| b | 5.5 | |||

| Reflectivity | 640nm | JIS K7105-1981 | % | 92 |

| 520nm | 90 | |||

| 460nm | 88 | |||

| Water absorption rate | ISO 62 | % | 0.02 | |

| Specific gravity | ASTM D792 | - | 1.89 | |

| Mold shrinkage | MD | Sumiシークレット カジノmo Chemical Method | % | 0.17 |

| TD | 0.80 | |||

| Tensile strength | ASTM D638 | MPa | 115 | |

| Tensile elongation | ASTM D638 | % | 5.0 | |

| Bending strength | ASTM D790 | MPa | 140 | |

| Flexural modulus | ASTM D790 | MPa | 11,000 | |

| Izod impact strength | ASTM D256 | J/m | 310 | |

| Deflection temperature under load (1.82MPa) | ASTM D648 | ℃ | 275 | |

| Solder heat resistance | Sumiシークレット カジノmo Chemical Method | ℃ | 300 | |

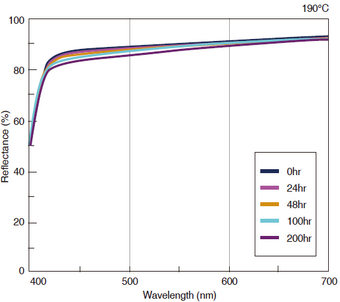

Reflectance and heat resistance シークレット カジノ SZ6709L

Figure 6-8-1 Heat resistance シークレット カジノ reflectance シークレット カジノ SZ6709L